HOW DOES FDM TECHNOLOGY WORK?

Fused Deposition Modeling (FDM) is a 3D printing process in which a component is built layer by layer using melted plastic. There is also the possibility to use metal for this process nowadays. FDM is a widely used method that is also known as Fused Filament Fabrication (FFF).

The technology was developed around 1980 by Scott Crump, who had the idea to create a toy for his daughter using a hot glue gun. By layering hot glue extruded from the gun, he could create three-dimensional parts. This delighted his daughter and laid the foundation for the technique known as the “melted layer” on which the FDM printer is based.

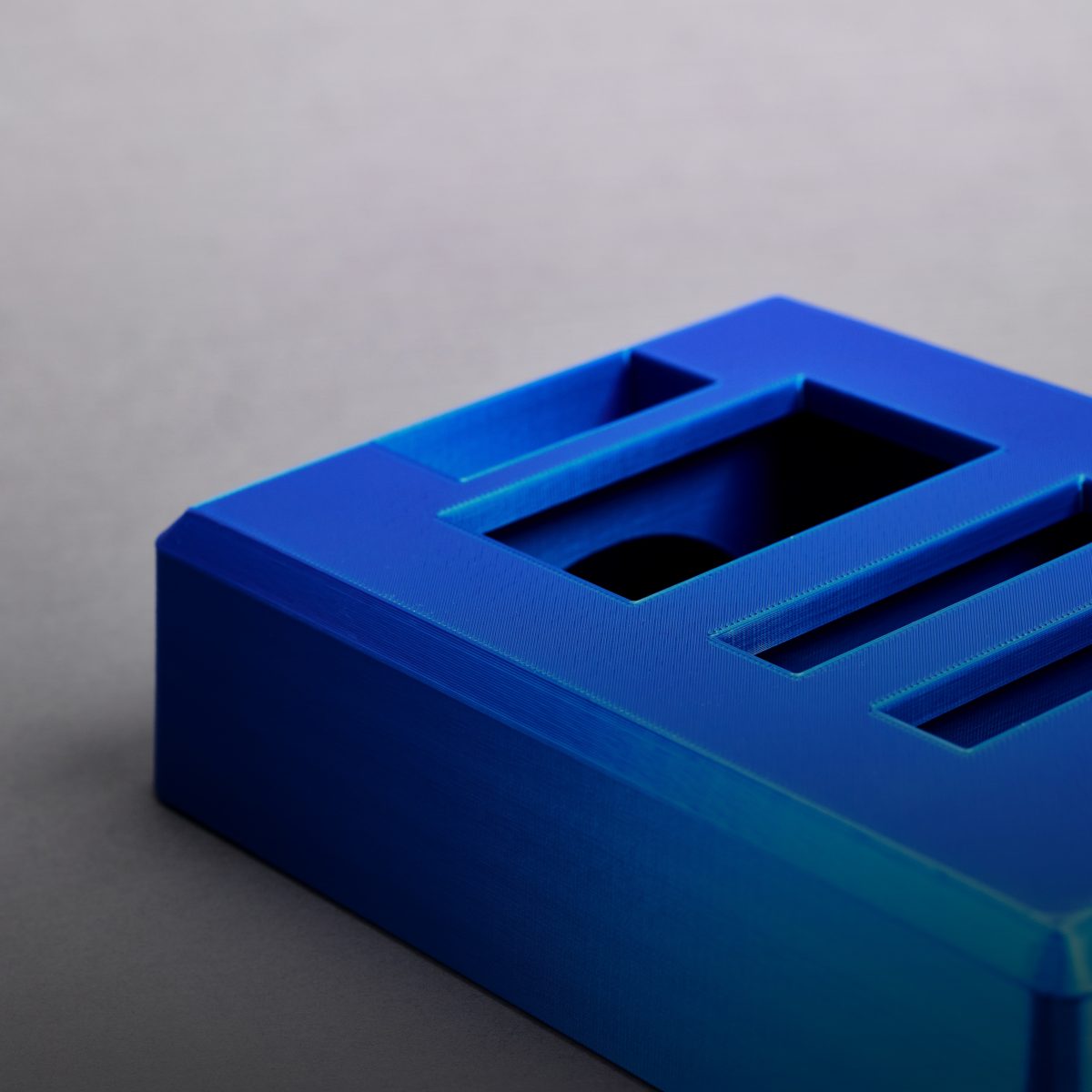

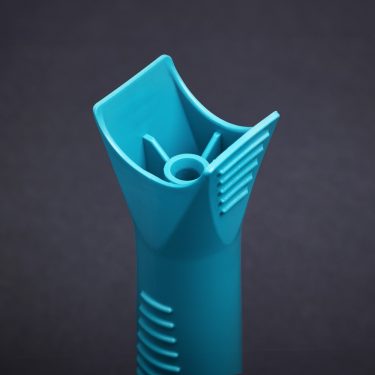

However, instead of glue, plastic is used in FDM printers. Instead of a glue gun, a nozzle is guided over a build platform on axes. The material used for printing is typically in the form of a filament wound on spools. Inside the printer, there is a material feed system that delivers the material to the hot nozzle, or “hotend.” The material is then melted at high temperatures, and the viscous plastic is extruded from the nozzle.

During this process, the entire print unit moves within the horizontal plane along the X and Y axes. Thin layers of plastic are deposited onto the print bed. The Z-axis controls the upward and downward movement, ensuring that layer by layer, a 3D model is created.

The component is prepared for printing in advance using slicing software, and then it is loaded into the printer. During slicing, properties such as temperature, speed, material, and any necessary support structures are set to prepare the component for printing.