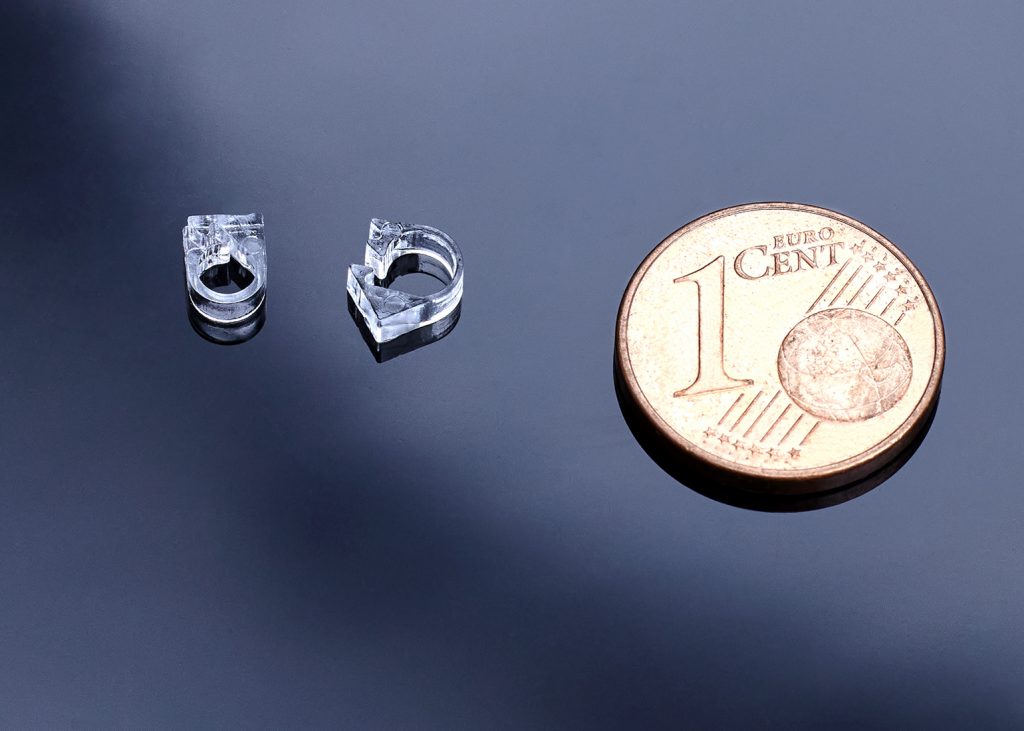

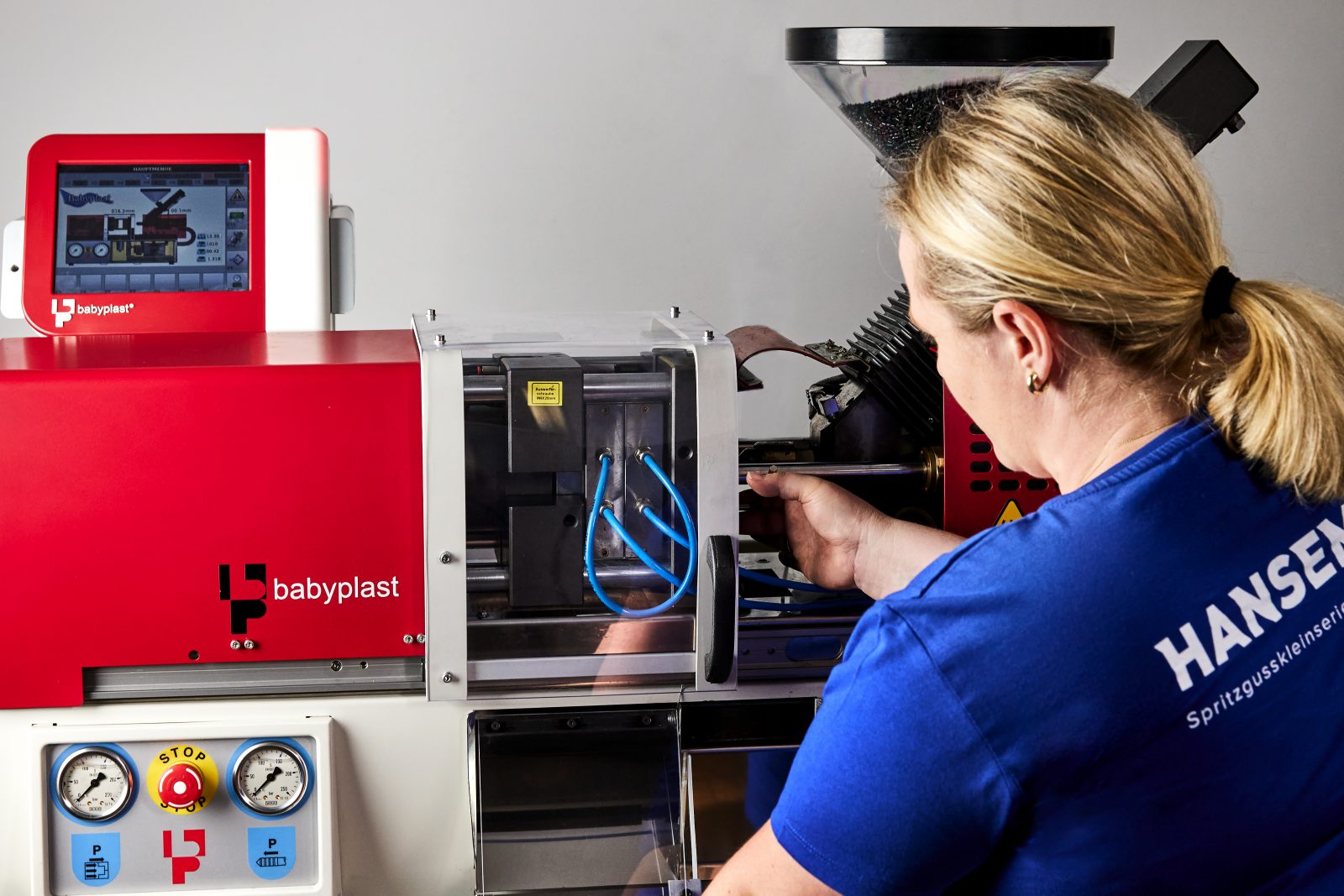

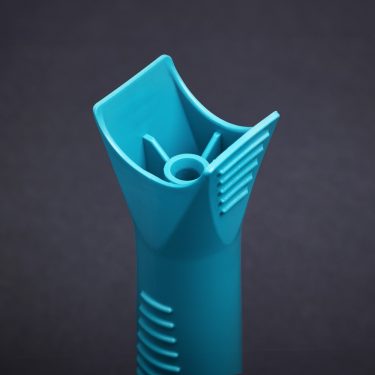

Micro injection moulding is a highly precise manufacturing process in plastic processing. In this process, tiny plastic parts are produced with the utmost precision and tight tolerances.

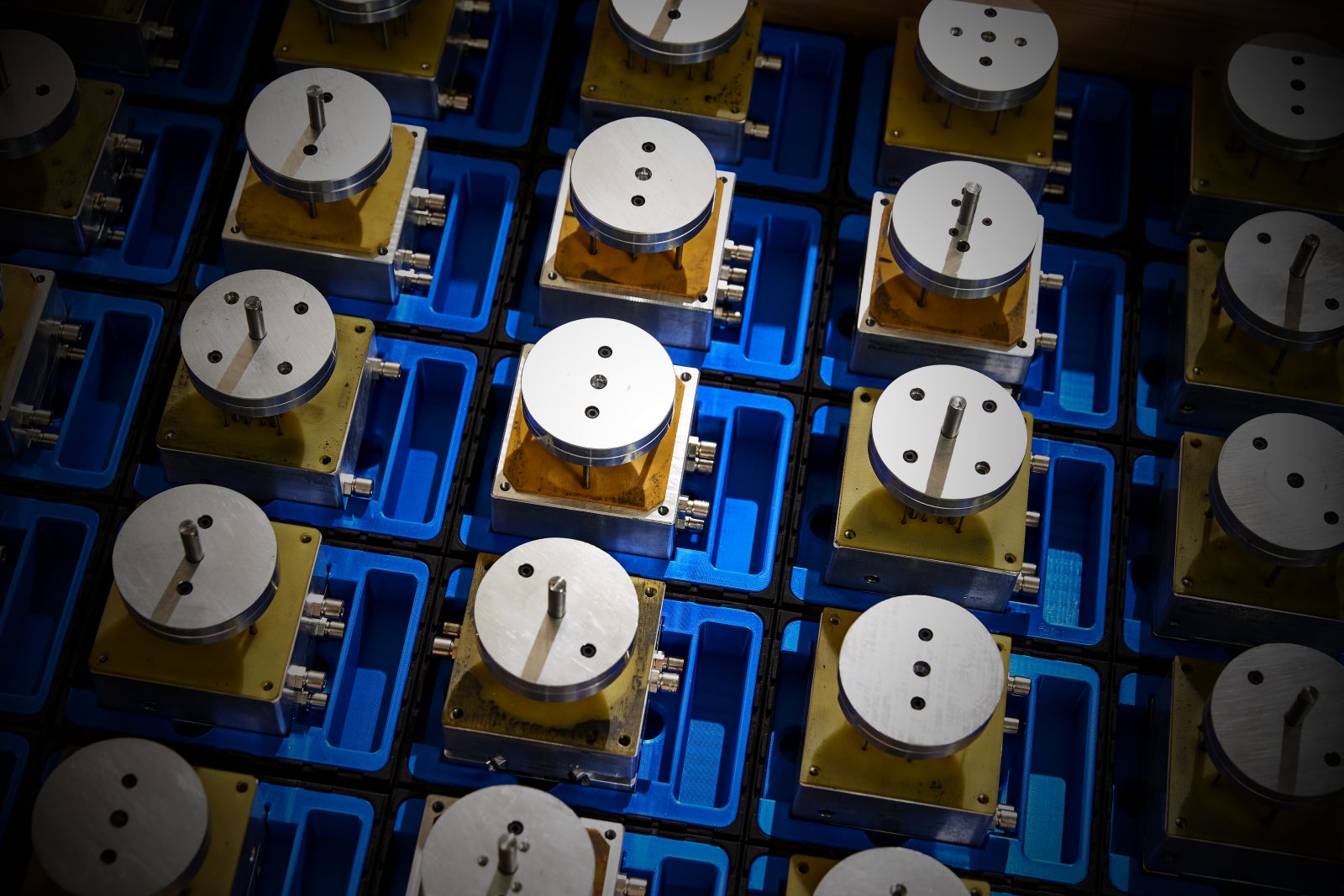

The process is similar to conventional injection molding, but the key difference lies in the fact that the tools and machines in micro injection molding are designed for small dimensions and the required precision. This method is used in industries such as medical technology, electronics, and microsystems engineering, where it is used to manufacture miniature components, sensors, and parts in small series and prototypes. Micro injection molding enables the production of precise and complex parts that are used in various applications.