We process the following materials:

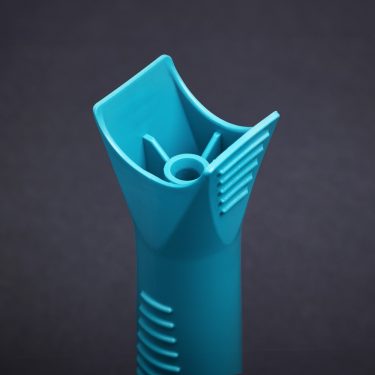

Thermoplastic Plastics

All common thermoplastic plastics can be processed on our injection molding machines. Thermoplastics include materials such as POM, PP, PE, ABS, PC, PA66, PA6, PC-ABS, PEEK, which are also available with various fillers. Fillers used include mineral fibers, glass fibers, carbon fibers, glass beads, and several others.

Thermoplastic Elastomers

We can also easily process thermoplastic elastomers such as TPE or TPV.

Silicone

For LSR (Liquid Silicone Rubber) processing, we have built molds multiple times. The injection molding process is carried out with a partner.