Good surfaces

Cost-effective parts

Fast prototyping

SLA 3D Printing Service

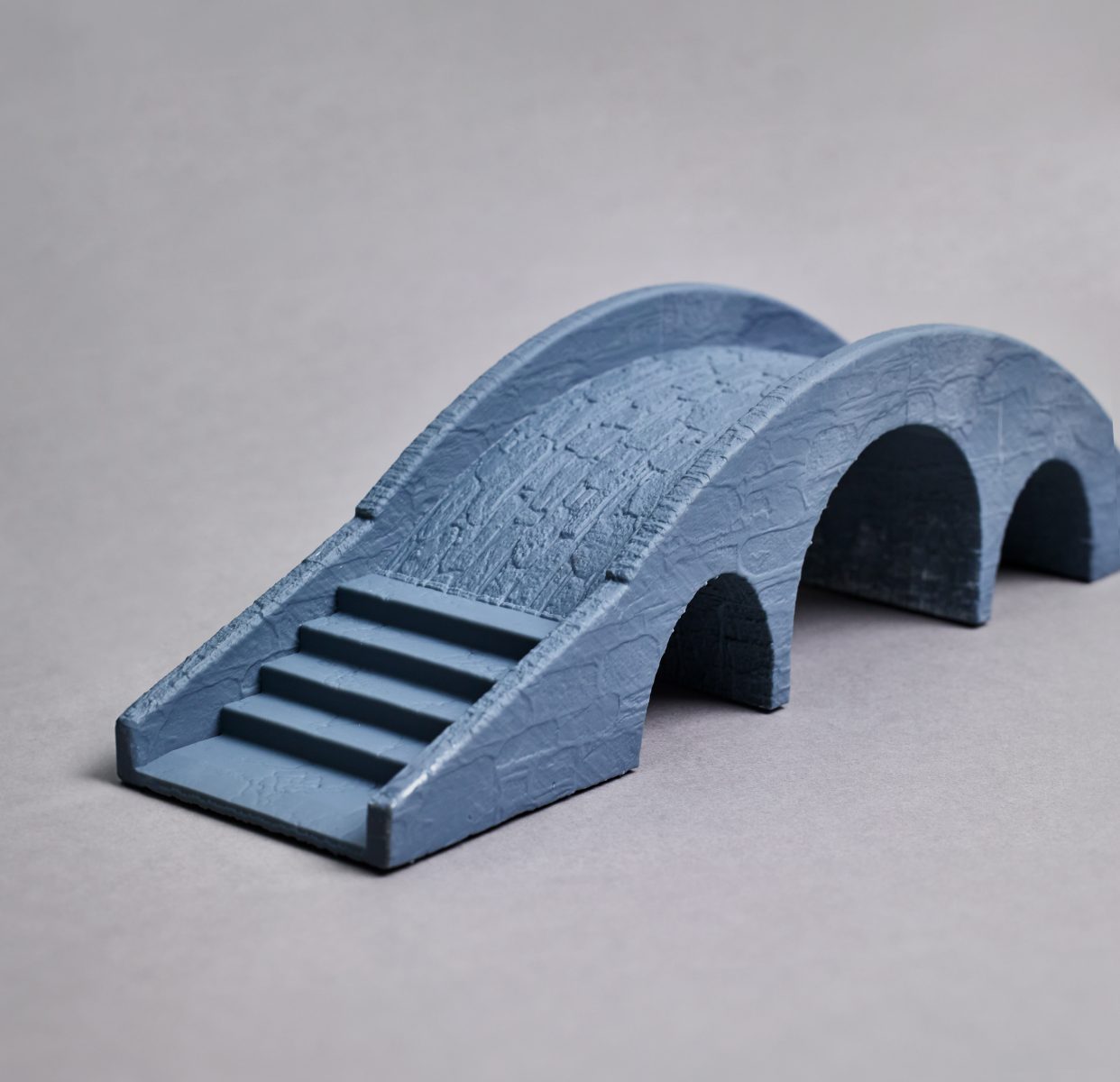

Our SLA printing service is the perfect solution for precise and detailed 3D printing projects. With stereolithography technology, we offer you the ability to create impressive prototypes and end products. SLA printing enables exceptionally high resolution and smooth surfaces, which is crucial for demanding applications.

We use a wide range of photopolymer materials, including biocompatible and heat-resistant variants, to meet your specific requirements.

Stereolithographie (SLA):

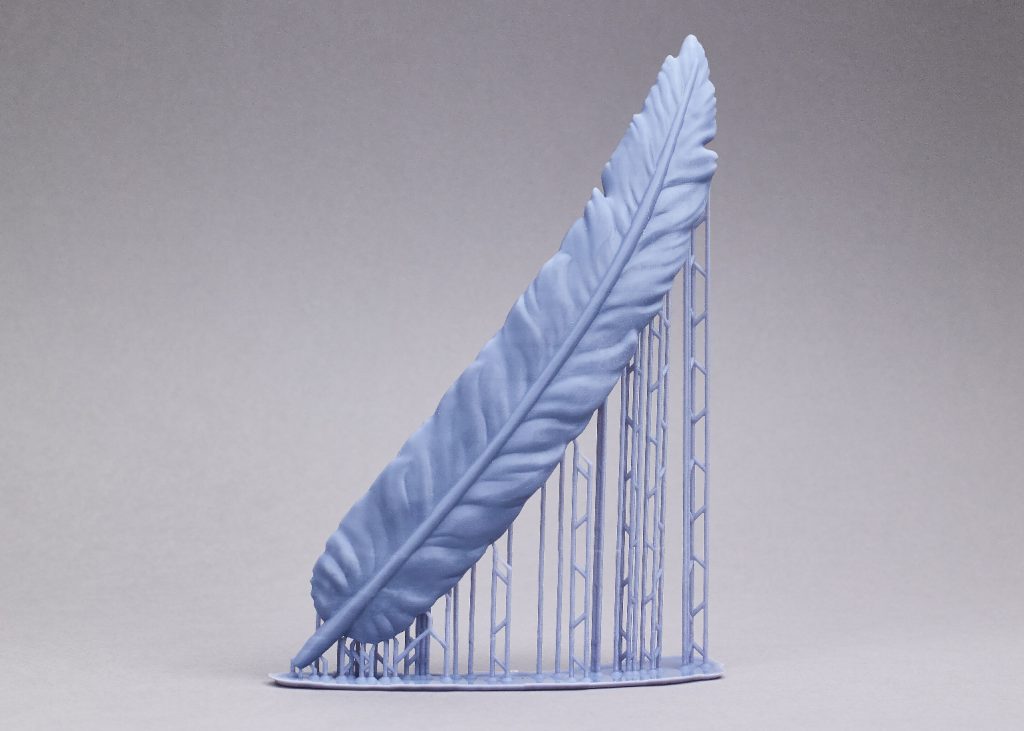

Stereolithography is a 3D printing process that uses a UV laser to cure liquid photopolymer in layers. This method allows for the precise creation of detailed and complex parts with a smooth surface.

High Resolution:

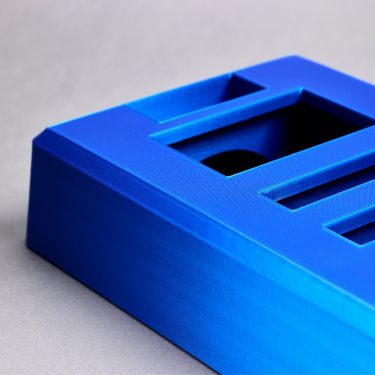

SLA printers offer exceptionally high resolution, enabling the production of fine details and complex geometries with high accuracy.SLA printers offer exceptionally high resolution, enabling the production of fine details and complex geometries with high accuracy.

Prototypes and End Products:

The SLA process is used in prototype development as well as for the production of end products, especially in fields like medical technology, jewelry design, and product design.

Material Variety:

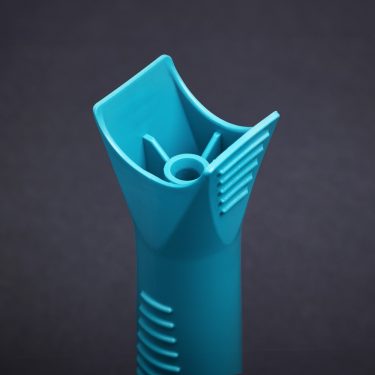

A variety of photopolymer materials are available, including biocompatible and heat-resistant options, to meet the requirements of different applications.

Application areas in SLA 3D-printing

Application areas in SLA 3D printing are highly diverse. In the field of prototype development, SLA is very popular due to its printing speed. Depending on the printer's quality, functional parts can even be produced immediately, significantly speeding up the development process.

For small-batch production, SLA is an ideal choice due to its ability to create highly precise and finely structured parts with exceptionally smooth surfaces. This allows companies to cost-effectively manufacture high-quality products in limited quantities.

SLA (Stereolithography) and FDM (Fused Deposition Modeling) are two different 3D printing processes that differ in several key aspects:

- Operation:

- SLA: SLA involves the application of liquid photopolymer resin in layers, which is then cured using a UV laser. The printing process occurs from top to bottom.

- FDM: FDM, on the other hand, uses thermoplastic filament that is melted through a heated nozzle and built up layer by layer. The printing process occurs from the bottom to the top.

- Precision and Detail:

- SLA: SLA printers typically offer higher precision and detail. They can create finer details and smoother surfaces.

- FDM: FDM printers have limited precision and can create less detailed models due to the layer thickness being determined by the nozzle size.

- Materials:

- SLA: SLA printers use photopolymer resins available in various formulations, including biocompatible and heat-resistant materials.

- FDM: FDM printers use a wide range of thermoplastic filaments, including PLA, ABS, PETG, and more.

- Post-processing:

- SLA: SLA models often require post-processing to remove excess resin and smooth the surfaces. Curing of the models takes place in a UV chamber.

- FDM: FDM models typically require less post-processing and cure during printing.

- Applications:

- SLA: SLA printing is frequently used in applications that require high precision, such as medical technology, jewelry design, and high-quality prototypes.

- FDM: FDM is often used in applications where functionality and strength are more critical than extreme detail. This includes prototyping, product design, architectural models, and more.

Both methods have their own advantages and disadvantages and are chosen based on the specific requirements of a project. The choice between SLA and FDM depends on factors such as precision, material selection, and application area.

Do you need SLA 3D printed components?

Feel free to contact us so that we can provide you with a quote.