Rapid tooling

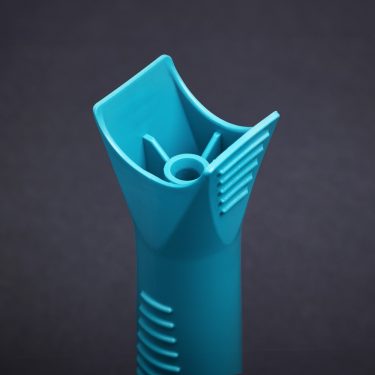

original material

Prices starting from €990

Fast delivery time

Rapid Tooling - What is it?

Rapid Tooling is a term from the field of generative manufacturing processes and can also be simply translated as "fast tooling."

It primarily concerns tooling and mould making, specifically the production of injection moulds and their components.

Rapid Tooling is also an umbrella term for all manufacturing processes where injection molds are directly produced from 3D CAD data.

Rapid Prototyping

Rapid Tooling enables the rapid creation of prototypes to test and refine design concepts

Cost-efficient production

With Rapid Tooling, you can cost-effectively create tools for mass production, saving time and resources

Customized Solutions

Rapid Tooling provides customized tools tailored to your specific requirements, enabling the production of high-quality parts.

Flexibility and agility

Thanks to Rapid Tooling, you can quickly respond to market changes and efficiently adapt production processes.

WHAT ARE THE ADVANTAGES OF RAPID TOOLING?

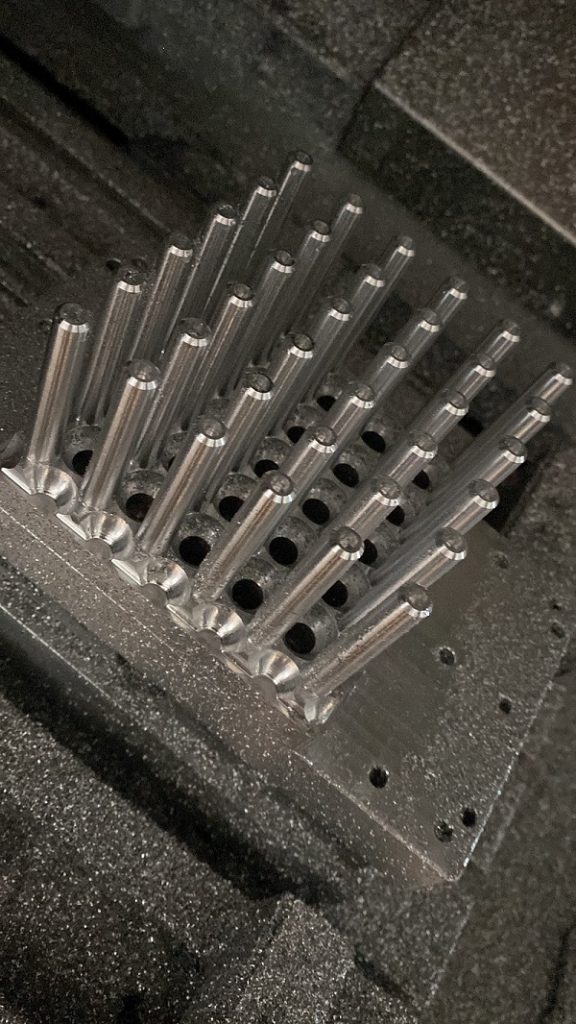

The Rapid Tooling process allows us to produce high-strength aluminum injection moulds quickly and cost-effectively.

- Rapid production of complex geometries.

- Cost-effective production of small batches and prototypes.

- Prototypes closely resemble serial production with original materials.

By applying the principles of a production tool but simplified and expedited, we can use Rapid Tooling to create a prototype with the quality of a production part.

Do you need injection-moulded parts?

Please feel free to contact us so that we can provide you with a quote.